In the fast-paced world of electronics manufacturing, precision and control are paramount. As technology advances, the demand for smaller, faster, and more efficient electronic components continues to rise. One crucial element in achieving these goals is the use of argon gas cylinders. Argon, an inert gas, plays a pivotal role in various stages of electronics manufacturing, ensuring the integrity, reliability, and performance of electronic devices.

1. Soldering and Welding:

Argon gas is commonly utilized in electronics manufacturing during the soldering and welding processes. The inert nature of argon makes it an ideal shield gas, preventing oxidation and ensuring a clean environment for these intricate operations. Soldering and welding are critical steps in the assembly of electronic components, and the use of argon gas helps maintain the quality and reliability of the connections.

2. Plasma Cutting and Etching:

In the fabrication of microelectronic circuits, plasma cutting and etching are essential processes. Argon gas is often employed as a plasma gas during these operations. The high-energy plasma created by argon assists in accurately cutting and etching materials at the microscopic level, enabling the production of intricate circuit patterns with precision and efficiency.

3. Cooling and Thermal Management:

Thermal management is a significant concern in electronics manufacturing, particularly when dealing with high-performance components. Argon gas is employed as a cooling medium in certain applications, efficiently dissipating heat and maintaining optimal operating temperatures. This is crucial for preventing overheating, which can lead to component failure and reduced overall device performance.

4. Controlled Atmosphere Environments:

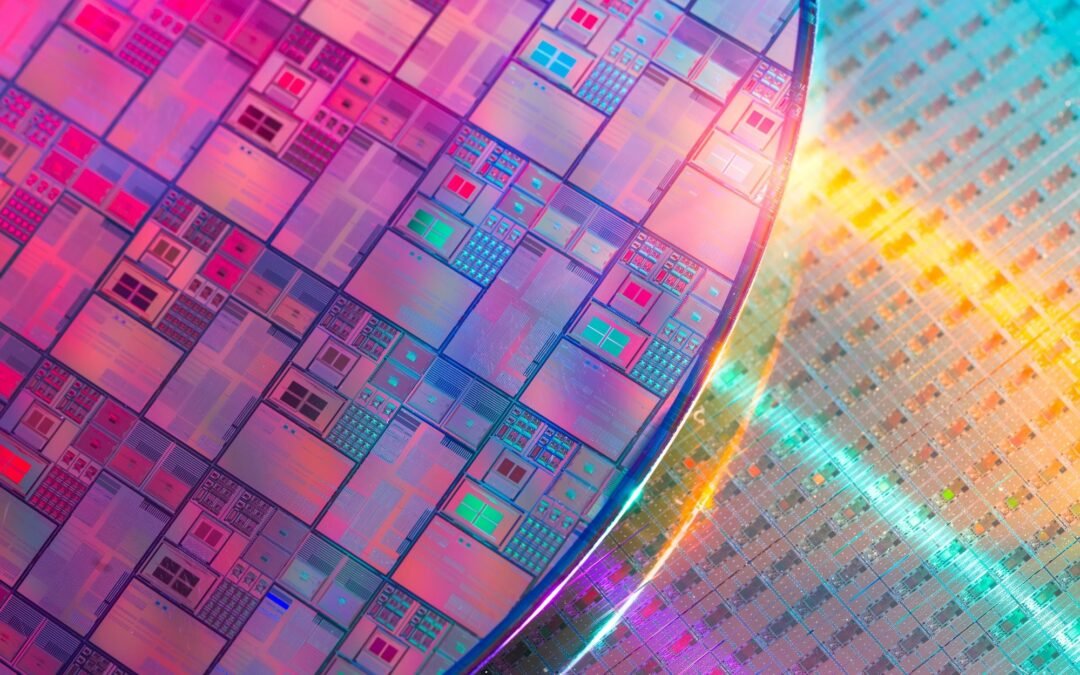

Certain electronic components, especially those based on sensitive materials like semiconductors, require a controlled atmosphere during manufacturing. Argon gas, due to its inert and stable properties, is utilized to create controlled environments within manufacturing chambers. This ensures that the components are produced in conditions free from contaminants and unwanted reactions, resulting in higher quality and more reliable electronic devices.

5. Display Manufacturing:

In the production of advanced display technologies such as OLEDs (Organic Light-Emitting Diodes), argon gas is used to create an inert environment. This prevents the degradation of sensitive organic materials during the manufacturing process, contributing to the longevity and performance of the display.

Conclusion:

In conclusion, argon gas cylinders play a crucial role in the electronics manufacturing industry, contributing to the creation of high-performance and reliable electronic devices. From soldering and welding to plasma cutting and controlled atmosphere environments, argon’s inert properties are harnessed to ensure precision, cleanliness, and thermal stability during various manufacturing processes. As the electronics industry continues to evolve, the importance of argon gas in achieving the desired quality and performance of electronic components remains undeniable.